Product

Industrial Drum Heaters

Nicropad industries Industrial Drum Heaters systems specialize in melting thick materials stored in standard drums with precision and speed, offering two distinct methods of drum heating: metallic heaters and flexible drum heating pads.

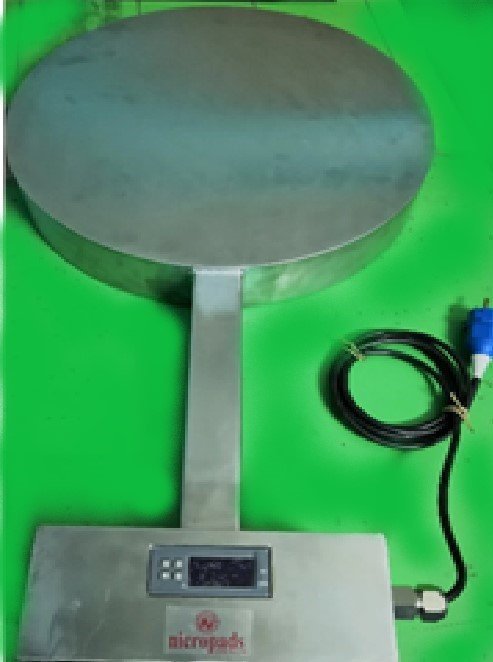

- Metallic Drum Heaters (MDHs):

A metallic Industrial drum heater comprises two halves connected on one side by hinges and securely connected at both ends by locking mechanisms. It is secured together using 3mm M.S. (Mild Steel) inner sheathing with an outer shell of 1mm M.S. sheathing to form its construction.

Movement: With its castors attached, a drum heater can easily be transported to its desired drum location.

Heating System: Our Heating System features six flexible heating pads – three on either side – strategically arranged to achieve uniform inner sheath heating without heat escaping into its surroundings. For optimal heat retention and minimum external loss, an 80mm thick insulation layer is attached to minimize heat loss through convection currents. Alternatively, options like tubular heaters or mineral-insulated cables may also be provided depending on specific application needs or cost considerations based on which they can provide solutions suited to you; please see our brochure for complete information. A horizontal model is also available!

Power Load: Our total load consists of six heaters with individual 750W ratings connected to single-phase A.C. power supplies for single-phase operation and provided single-phase power from three different A.C. circuits, producing an aggregate wattage totaling 4.5 K.W., which connects directly into a 3-phase system; we may expand this load up to 9 K.W. for any given experimentation cycle if desired.

Control System: For efficient operation of drum heaters, an ideal control panel containing a digital temperature indicator/controller and PT-100 thermocouple can be provided either separately from or attached directly to the drum heater for user-friendly operation. A base heater capable of producing 1 K.W. of heating power may also be included to facilitate rapid heating processes.

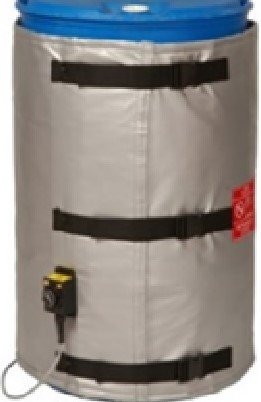

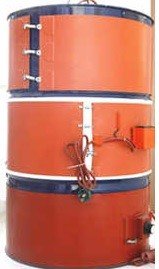

- FLEXIBLE HEATING PADS:

Nicropad industries offers flexible electric surface heating pads designed to wrap around drums to facilitate the melting of viscous materials. Crafted using nichrome wire, these heating pads may be covered by fiberglass cloth, Teflon-coated fiberglass cloth or silicon-coated glass cloth based on desired temperatures and site conditions for efficient melting action.

Nicropad industries Industrial Drum Heaters are specially designed to offer optimal contact with drum surfaces while eliminating air gaps – leading to highly effective heating across an entire drum. This design creates even, efficient heat distribution that’s both fast and evenly heated.

Insulation: For added warmth protection and to reduce heat loss to its surroundings, each heating element in this pad is wrapped with fiberglass yarn insulation and protected with a 40mm-thick layer of protection material.

Usage: Depending on your application, one or multiple pads can be used on each drum. They come equipped with various wattages for ease of control via an associated control panel or thermostat for simple operation.